In this video lesson, the “E+M” channel talked about what an electromagnet is. He also showed how to make it by hand with a supply voltage of 12 volts and performed a series of experiments using it. Showed how to increase efficiency.

First, a little theory of history. In the early 19th century, Danish physicist Oersted discovered the connection between electricity and magnetism. A current passing through a conductor located next to the compass deflects its needle towards the conductor. This indicates the presence of a magnetic field around the conductor. It also turned out that if you wind a conductor into a coil, its magnetic properties will increase. In a coil of wire, the so-called solenoid, magnetic lines are formed, the same as in a permanent magnet.

Depending on which side we carry the coil to the compass, it will deviate in one direction or another. Since two poles have formed in the coil: north and south. It is possible to change the direction of electric current when the poles are reversed. For the experiment, the author of the channel wound 2 identical coils. The first coil is 260 turns, resistance 7 ohms. 2 is twice as much. 520 turns, resistance 15 ohms. Power will be supplied from a DC source. Voltage 12 volts. In this case, it is a computer power supply. A lead-acid battery will also work.

Let's start experiments with the first coil, which has 260 turns. The multimeter is set to current measurement mode. It will show the current in amps flowing through the coil. As you can see, the indicator is 1.4 amperes. This is enough to attract small metal objects. Let's try a larger object. Let it be an iron ruble. The coil cannot handle this load. Let's try the same experiment with the second coil. The current here is 0.7 amperes. This is 2 times less than 1. At the same voltage of 12 volts. She also cannot attract the ruble. What can we do to increase the magnetic properties of our coil? Let's try to install an iron core. To do this we use a bolt. Now it will act as a magnetic circuit. The latter promotes the passage of magnetic flux through itself and increases the corresponding properties of the solenoid. Now our design has turned into an electromagnet. He can already handle the ruble with ease. The current remained the same, 1.4 amperes.

Let's experiment further and see how many of these objects the magnetic coil can attract. The electromagnet has heated up, which means its resistance has increased. The higher the resistance, the lower the current. The less magnetic field the coil creates. Let's let the electromagnet cool completely and repeat the experiments. This time the load will be 12 coins. As you can see, the lower coins began to fall off on their own as the current decreased. No matter how much the presenter tried to experiment, he managed to raise no more than this load.

Let's carry out the same experiment with the second coil. It has twice as many turns. Let's see if it is stronger than the previous one. Watch the continuation of the 12 volt electromagnet in the video from 6 minutes.

izobreteniya.net

How to make a homemade electromagnet

This video from the Kreosan channel shows how to make your own electric magnet. You need to take the transformer from the microwave, cut it and remove the windings. Other transformers will also work. But powerful and available only in microwaves.

We need a primary winding. We just turned it on, and it’s already starting to vibrate. What will happen when it attracts iron? It's time to try out the electromagnet. It can be supplied with 12, 24, 36, 48, 110, 220 volts. In this case, there can be direct and alternating current. Let's turn on the laptop battery and see what a homemade electromagnet can do at a voltage of 12 volts. We take a nut and, with the participation of an electromagnet, crush it with a door. As you can see, he easily dealt with the nut. Let's try to lift something heavier. For example, a manhole cover.

There is an idea for a simple pulsation meter.

The simplest electromagnet in 5 minutes

Further. Another channel (HM Show) released a video on the same topic. It showed how to make a simple electromagnet in 5 minutes. To make a device with your own hands, you will need a steel rod, copper wire and any insulating material.

First, we insulate the steel rod with construction tape and cut off the excess material. It is necessary to wrap the copper wire around the insulating material so that there are as few air gaps as possible. The strength of the magnet depends on this, as well as the thickness of the copper wire, the number of turns and the current strength. These indicators need to be selected experimentally. After winding the wire, wrap it with insulating material.

We strip the ends of the wire. We connect the magnet to the power supply and apply a voltage of four volts with a current of 1 ampere. As you can see, the bolts do not magnetize well. To strengthen the magnet, we increase the current to 1.9 amperes and the result immediately changes for the better! With this current strength we can now lift not only bolts, but also wire cutters and pliers. Try making it using a battery, and write the result in the comments.

izobreteniya.net

How to make an electromagnet with your own hands at home

What you will need

Additionally:

This is a general recommendation since the electromagnet is made for a specific purpose. Based on this, the components of the circuit are selected. And if it is done at home, then there cannot be any standard - whatever is at hand will do. For example, in relation to the first point, a nail, a lock shackle, or a piece of iron rod are often used as a core - the choice of options is huge.

Manufacturing procedure

Winding

What to consider

That is why you should not rely on third-party advice from “experienced and experienced” people. There is a specific core (with its own magnetic conductivity, dimensions, cross-section), wire and power source. Therefore, you will have to experiment, achieving the optimal combination of parameters such as current, resistance and temperature.

Connection

- Soldering copper and connecting wires. Although this is not essential, you can twist it by insulating it with a PVC pipe or adhesive tape.

It is not difficult to select an iron core based on its internal cross-section. For ease of control, you need to include a rheostat (variable resistance) in the circuit. Accordingly, such an electric magnet is already connected to the outlet. The force of attraction is regulated by changing the R circuit.

Making an electromagnet is quite simple. Everything else depends on the patience and ingenuity of the master. You may have to experiment to get what you need - with the supply voltage, wire cross-section, and so on. Any homemade product requires not only a creative approach, but also time. If you do not regret it, then an excellent result is guaranteed.

electroadvice.ru

Regardless of why a person needs a magnet, it can easily be made at home. When you have such a thing at hand, you can use it not only to have fun picking up various small pieces of iron from the table, but also to find a useful use for it, for example, to find a needle dropped on the carpet. In this article you will learn how easy it is to make an electromagnet with your own hands at home.

A little physics

As we remember (or don’t remember) from physics lessons, in order to convert electric current into a magnetic field, we need to create induction. Inductance is created using an ordinary coil, inside which this field arises and is transmitted to the steel core around which the coil is wound.

Thus, depending on the polarity, one end of the core will emit a field with a minus sign, and the opposite end will emit a field with a plus sign. But visual magnetic abilities are not affected in any way by polarity. So, when you are done with physics, you can begin decisive action to create a simple electromagnet with your own hands.

Materials for making the simplest magnet

First of all, we need any inductor with a copper wire wound around the core. This can be a regular transformer from any power supply. An excellent way to create electromagnets is to wind them around the narrowed back of picture tubes of old monitors or televisions. The conductor threads in transformers are protected by insulation consisting of an almost invisible layer of special varnish that prevents the passage of electric current, which is exactly what we need. In addition to the indicated conductors, to create an electromagnet with your own hands you also need to prepare:

- A regular one and a half volt battery.

- Scotch tape or tape.

- Sharp knife.

- Hundreds of nails.

The process of making a simple magnet

We start by removing the wires from the transformer. As a rule, its middle is located inside the steel frame. You can, after removing the surface insulation on the coil, simply unwind the wire, dragging it between the frames and the coil. Since we don't need a lot of wire, this method is the most acceptable here. When we have released enough wire, we do the following:

- We wind the wire removed from the transformer coil around a nail, which will serve as a steel core for our electromagnet. It is advisable to make turns as often as possible, pressing them tightly against each other. Do not forget to leave a long end of the wire at the initial turn, through which our electromagnet will be powered to one of the poles of the battery.

- When we reach the opposite end of the nail, we also leave a long conductor for powering. We cut off the excess wire with a knife. To prevent the spiral we wound from unraveling, you can wrap it with tape or tape.

- We strip both ends of the wire coming from the wound nail from the insulating varnish with a knife.

- We lean one end of the stripped conductor against the positive of the battery and secure it with tape or tape so that the contact is well maintained.

- We wind the other end to the minus in the same way.

The electromagnet is ready for use. By scattering metal clips or tacks on the table, you can check its functionality.

How to make a more powerful magnet?

How to make an electromagnet with more powerful magnetic properties with your own hands? The strength of magnetism is influenced by several factors, and the most important one is the electrical current of the battery we use. For example, by making an electromagnet from a square 4.5 volt battery, we will triple the strength of its magnetic properties. The 9-volt crown will give an even more powerful effect.

But do not forget that the stronger the electric current, the more turns will be required, since the resistance with a small number of turns will be too strong, which will lead to strong heating of the conductors. If they are heated too much, the insulating varnish may begin to melt, and the turns will begin to short-circuit to each other or to the steel core. Both will sooner or later lead to a short circuit.

Also, the strength of magnetism depends on the number of turns around the magnet core. The more there are, the stronger the induction field will be, and the stronger the magnet will be.

Making a more powerful magnet

Let's try to make a 12 volt electromagnet with our own hands. It will be powered by a 12-volt AC power supply or a 12-volt car battery. To manufacture it, we will need a much larger amount of copper conductor, and therefore we should initially remove the internal coil with copper wire from the prepared transformer. A grinder is the best way to extract it.

What we need for production:

- A steel horseshoe from a large padlock, which will serve as our core. In this case, it will be possible to magnetize the pieces of iron at both ends, which will further increase the lifting capacity of the magnet.

- Coil with copper wire in varnished insulation.

- Insulating tape.

- Unnecessary 12 volt power supply or car battery.

The process of making a powerful 12-volt magnet

Of course, any other massive steel pin can be used as a core. But a horseshoe from an old castle will do just fine. Its bend will serve as a kind of handle if we start lifting loads of impressive weight. So, in this case, the process of making an electromagnet with your own hands is as follows:

- We wind the wire from the transformer around one of the horseshoes. We place the coils as tightly as possible. The curve of the horseshoe will interfere a little, but that's okay. When the length of the side of the horseshoe ends, we lay the turns in the opposite direction, on top of the first row of turns. We make a total of 500 turns.

- When the winding of one half of the horseshoe is ready, wrap it with one layer of electrical tape. The original end of the wire, intended for recharge from a current source, is brought out to the upper part of the future handle. We wrap our coil on the horseshoe with another layer of electrical tape. We wind the other end of the conductor to the bending core of the handle and make another coil on the other side.

- We wind the wire on the opposite side of the horseshoe. We do everything the same as in the case of the first side. When 500 turns have been laid, we also remove the end of the wire for power supply from an energy source. For those who don't understand, the procedure is clearly shown in this video.

The final stage of making an electromagnet with your own hands is recharging to the energy source. If it is a battery, we extend the ends of the stripped conductors of our electromagnet using additional wires, which we connect to the battery terminals. If this is a power supply, cut off the plug going to the consumer, strip the wires and screw a wire from the electromagnet to each one. Insulate with electrical tape. We plug the power supply into the outlet. Congratulations. You have made with your own hands a powerful 12-volt electromagnet that is capable of lifting loads over 5 kg.

Such a device is convenient because its operation is easy to control using electric current - changing the poles, changing the force of attraction. In some matters it becomes truly indispensable, and is often used as a constructive element of various homemade products. It’s not difficult to make a simple electromagnet with your own hands, especially since almost everything you need can be found in every home.

- Any suitable sample made of iron (it is highly magnetic). This will be the core of the electromagnet.

- The wire is copper, always with insulation to prevent direct contact of the two metals. For a homemade electric magnet, the recommended cross-section is 0.5 (but not more than 1.0).

- DC source - battery, battery, power supply.

Additionally:

- Connecting wires for connecting an electromagnet.

- Soldering iron or electrical tape to secure contacts.

This is a general recommendation since the electromagnet is made for a specific purpose. Based on this, the components of the circuit are selected. And if it is done at home, then there cannot be any standard - whatever is at hand will do. For example, in relation to the first point, a nail, a lock shackle, or a piece of iron rod are often used as a core - the choice of options is huge.

Manufacturing procedure

Winding

The copper wire is carefully wound onto the core, turn by turn. With such scrupulousness, the efficiency of the electromagnet will be the maximum possible. After the first “pass” along the iron sample, the wire is laid in a second layer, sometimes a third. It depends on how much power the device requires. But the direction of winding must remain unchanged, otherwise the magnetic field will become “unbalanced”, and the electromagnet will hardly be able to attract anything to itself.

To understand the meaning of the ongoing processes, it is enough to remember the physics lessons from the high school course - moving electrons, the EMF they create, the direction of its rotation.

After winding is completed, the wire is cut so that the leads can be conveniently connected to the power source. If it's a battery, then directly. When using a power supply, battery or other device, you will need connecting wires.

What to consider

There are certain difficulties with the number of layers.

- As turns increase, reactance increases. This means that the current strength will begin to decrease, and the attraction will become weaker.

- On the other hand, increasing the current rating will cause the winding to heat up.

That is why you should not rely on third-party advice from “experienced and experienced” people. There is a specific core (with its own magnetic conductivity, dimensions, cross-section), wire and power source. Therefore, you will have to experiment, achieving the optimal combination of parameters such as current, resistance and temperature.

The operating principle of the electromagnet is described in detail in the following video:

Connection

- Cleaning the copper terminals. The wire is initially coated with several layers of varnish (depending on the brand), and it is known to be an insulator.

- Soldering copper and connecting wires. Although this is not essential, you can twist it by insulating it or using adhesive tape.

- Fixing the second ends of the wires on the clamps. For example, the “crocodile” type. Such removable contacts will allow you to easily change the poles of the electromagnet, if necessary during its use.

- To make a powerful electromagnet, home craftsmen often use a coil from an MP (magnetic starter), relays, or contactors. They are available for both 220 and 380 V.

It is not difficult to select an iron core based on its internal cross-section. For ease of control, you need to include a rheostat (variable resistance) in the circuit. Accordingly, such an electric magnet is already connected to the outlet. The force of attraction is regulated by changing the R chain.

- You can increase the power of an electromagnet by increasing the cross-section of the core. But only up to certain limits. And here you have to experiment.

- Before making an electric magnet, you need to make sure that the selected iron sample is suitable for this. The check is quite simple. Take a regular magnet; There are a lot of things in the house on such “suction cups”. If it attracts the part selected for the core, it can be used. If the result is negative or “weak,” it is better to look for another sample.

Making an electromagnet is quite simple. Everything else depends on the patience and ingenuity of the master. You may have to experiment to get what you need - with the supply voltage, wire cross-section, and so on. Any homemade product requires not only a creative approach, but also time. If you do not regret it, then an excellent result is guaranteed.

Along with permanent magnets, since the 19th century, people began to actively use variable magnets in technology and everyday life, the operation of which can be regulated by the supply of electric current. Structurally, a simple electromagnet is a coil of electrical insulating material with a wire wound on it. If you have a minimum set of materials and tools, it is not difficult to make an electromagnet yourself. We will tell you how to do it in this article.

When electric current passes through a conductor, a magnetic field appears around the wire; when the current is turned off, the field disappears. To enhance the magnetic properties, a steel core can be introduced into the center of the coil or the current can be increased.

Use of electromagnets in everyday life

Electromagnets can be used to solve a number of problems:

- for collecting and removing steel filings or small steel fasteners;

- in the process of making various games and toys together with children;

- for electrifying screwdrivers and bits, which allows you to magnetize screws and facilitate the process of screwing them;

- for conducting various experiments on electromagnetism.

Making a simple electromagnet

The simplest electromagnet, quite suitable for solving a small range of practical household problems, can be made with your own hands without using a coil.

For work, prepare the following materials:

- steel rod with a diameter of 5-8 millimeters or a 100 nail;

- copper wire in varnish insulation with a diameter of 0.1-0.3 millimeters;

- two pieces of 20 centimeters of copper wire in PVC insulation;

- insulating tape;

- source of electricity (battery, accumulator, etc.).

From tools, prepare scissors or wire cutters (side cutters) for cutting wires, pliers, and a lighter.

The first stage is winding the electrical wire. Wind several hundred turns of thin wire directly onto the steel core (nail). Carrying out this process manually takes quite a long time. Use a simple winding device. Clamp the nail into the chuck of a screwdriver or electric drill, turn on the tool and, guiding the wire, wind it. Wrap pieces of larger diameter wire to the ends of the wound wire and insulate the contact points with insulating tape.

When operating the magnet, all that remains is to connect the free ends of the wires to the poles of the current source. The distribution of connection polarity does not affect the operation of the device.

Using the switch

For ease of use, we suggest slightly improving the resulting diagram. Two more elements should be added to the above list. The first of them is the third wire in PVC insulation. The second is a switch of any type (keyboard, push-button, etc.).

Thus, the electromagnet connection diagram will look like this:

- the first wire connects one contact of the battery to the contact of the switch;

- the second wire connects the second contact of the switch with one of the contacts of the electromagnet wire;

the third wire completes the circuit, connecting the second contact of the electromagnet to the remaining contact of the battery.

Using a switch, turning on and off the electromagnet will be much more convenient.

Coil based electromagnet

A more complex electromagnet is made on the basis of a coil of electrical insulating material - cardboard, wood, plastic. If you don’t have such an element, it’s easy to make it yourself. Take a small tube from the indicated materials and glue a couple of washers with holes to it at the ends. It is better if the washers are located at a small distance from the ends of the coil.

Even a novice physicist can do this. The article offers three options for how to make an electromagnet at home. Try it, you will succeed!

In the first option there are instructions with details on how to make a simple electromagnet. Prepare:

- copper wire;

- nuts and bolt;

- tape (preferably paper);

- electrical tape;

- Well, a couple of hands with imagination.

Are you ready? We assemble the structure. First, washers are put on the bolt. Next, tape is wound (this will prevent a short circuit), everything is tightened with a nut. The result was the core of the electromagnet being constructed. Now the end of the wire is attached to the bolt thread. Begin to carefully wind the wire around the core, from turn to turn. Having wound the first layer, we return to the first turn. Now the second turn is wound. The sequence of operations is repeated several times. Each time, winding must be done carefully, one layer after another, from turn to turn.

Around the fifth layer, the number of turns decreases, but the density remains the same. As a result, we get a kind of “bulb”. After winding the last layer, wrap the spool with electrical tape. A simple electromagnet is ready.

How to make an electromagnet, option two. Prepare:

- enameled wire;

- pliers;

- cambric;

- nail;

- electrical tape;

- paper;

- plastic washers according to the diameter of the nail;

- power supply.

Use pliers to bite off the sharp tip of the nail. File this cut. The end should be even. Fire it in the oven and let it cool. Remove carbon deposits. Let's start with isolation. We put a cambric on the nail, install washers on both sides so that the winding does not go beyond the cambric. We wind the wire around the cambric in tight turns. When the first layer is ready, wrap the layer in paper and proceed to the next layer. More turns means a stronger electromagnet. Don't forget to bring the wires out after winding is complete. The ends are stripped and connected to any current source.

Option three. How to make a powerful electromagnet? This electromagnet, like the previous one, will work from electricity. This means that the power is regulated, i.e. it can be either added or subtracted. So, how to make a powerful electromagnet? Cooking:

- nail (you can take any size, just not small);

- copper wire (coil) of medium size in diameter;

- switch (any one you find);

- power unit;

- soldering iron;

- scissors.

Now let's get started. To begin with, a clarification: if there is no nail, it is quite possible to use an iron rod (or something similar). The main emphasis is on the material (iron) and the form itself. The rod must be long, not crooked. should be wound onto it evenly, without gaps. Now about the wire. As you already understood, only copper will do. Where to get? From any power supply. For example, a small transformer from a small generator. Focus on the diameter of the coil: it should not be too large. Ideally - medium sizes. Break (or cut) the plastic so you can unwind the wire faster. The entire coil will most likely not be needed.

Next step. We take a nail (or a found analogue) and wind the wire around it (evenly). Each turn should fit tightly to the previous one. I repeat: there should be no spaces. Wrap in several layers (minimum four). Do not accidentally break the coil when winding: breaking the connection will not allow the device being built to work. Now we draw two conductors: the beginning of the winding and the end of the winding. We clean both contacts. Carefully, carefully. Copper wire, as you know, is very, very fragile. Do not damage it, otherwise you will easily break the contact. After stripping, both contacts are connected to the power supply. And you can also go to the switch if you want.

That's all. Choose an option and try it. Good luck!

An electromagnet is an artificial magnet in which a magnetic field arises and is concentrated in a ferromagnetic core as a result of the passage of electric current through the winding surrounding it, i.e. When current is passed through the coil, the core placed inside it acquires the properties of a natural magnet.

The scope of application of electromagnets is very wide. They are used in electrical machines and devices, in automation devices, in medicine, and in various types of scientific research. Most often, electromagnets and solenoids are used to move some mechanisms, and in industries to lift loads.

For example, a lifting electromagnet is a very convenient, productive and economical mechanism: no maintenance personnel are required to secure and release the transported cargo. It is enough to place an electromagnet on the moving load and turn on the electric current in the electromagnet coil and the load will be attracted to the electromagnet, and to release the load you only need to turn off the current.

The design of an electromagnet is easy to replicate and is essentially nothing more than a core and a coil of conductor. In this article we will answer the question of how to make an electromagnet with your own hands?

How an electromagnet works (theory)

If an electric current flows through a conductor, a magnetic field is formed around this conductor. Since current can only flow when the circuit is closed, the conductor must be a closed loop, such as a circle, which is the simplest closed loop.

Previously, a conductor rolled into a circle was often used to observe the effect of current on a magnetic needle placed in its center. In this case, the arrow is at an equal distance from all parts of the conductor, making it easier to observe the effect of the current on the magnet.

To increase the effect of electric current on a magnet, you can first increase the current. However, if you bend a conductor through which some current flows twice around the circuit it covers, then the effect of the current on the magnet will double.

In this way, this action can be increased many times over by bending the conductor an appropriate number of times around a given circuit. The resulting conducting body, consisting of individual turns, the number of which can be arbitrary, is called a coil.

Let's remember the school physics course, namely that when an electric current flows through a conductor. If the conductor is rolled into a coil, the magnetic induction lines of all turns will add up, and the resulting magnetic field will be stronger than for a single conductor.

The magnetic field generated by electric current, in principle, has no significant differences compared to the magnetic field. If we return to electromagnets, the formula for its traction force looks like this:

F=40550∙B 2 ∙S,

where F is the traction force, kg (force is also measured in newtons, 1 kg = 9.81 N, or 1 N = 0.102 kg); B - induction, T; S is the cross-sectional area of the electromagnet, m2.

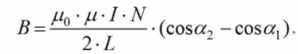

That is, the traction force of an electromagnet depends on the magnetic induction, consider its formula:

Here U0 is the magnetic constant (12.5*107 H/m), U is the magnetic permeability of the medium, N/L is the number of turns per unit length of the solenoid, I is the current strength.

It follows that the force with which a magnet attracts something depends on the current strength, the number of turns and the magnetic permeability of the medium. If there is no core in the coil, the medium is air.

Below is a table of relative magnetic permeabilities for different media. We see that for air it is equal to 1, and for other materials it is tens and even hundreds of times greater.

In electrical engineering, a special metal is used for cores; it is often called electrical or transformer steel. In the third line of the table you see “Iron with silicon” whose relative magnetic permeability is 7 * 103 or 7000 H/m.

This is the average value for transformer steel. It differs from the usual one precisely in the silicon content. In practice, its relative magnetic permeability depends on the applied field, but we will not go into details. What does the core do in the coil? An electrical steel core will enhance the magnetic field of the coil by approximately 7000-7500 times!

All you need to remember to begin with is that the material of the core inside the coil depends on it, and the force with which the electromagnet will pull depends on it.

Practice

One of the most popular experiments that are carried out to demonstrate the occurrence of a magnetic field around a conductor is the experiment with metal shavings. The conductor is covered with a sheet of paper and magnetic shavings are poured onto it, then an electric current is passed through the conductor, and the shavings change their location somehow on the sheet. It's almost an electromagnet.

But simply attracting metal shavings is not enough for an electromagnet. Therefore, you need to strengthen it, based on the above - you need to make a coil wound on a metal core. The simplest example would be insulated copper wire wound around a nail or bolt.

Such an electromagnet is capable of attracting various pins, scrapies, and the like.

As a wire, you can use either any wire in PVC or other insulation, or copper wire in varnish insulation such as PEL or PEV, which are used for windings of transformers, speakers, motors, etc. You can find it either new in reels, or reeled from the same transformers.

10 Nuances of making electromagnets in simple words:

1. The insulation along the entire length of the conductor must be uniform and intact so that there are no interturn short circuits.

2. Winding should go in one direction, like on a spool of thread, that is, you cannot bend the wire 180 degrees and go in the opposite direction. This is due to the fact that the resulting magnetic field will be equal to the algebraic sum of the fields of each turn, if you do not go into details, then the turns wound in the opposite direction will generate an electromagnetic field of the opposite sign, as a result the fields will be subtracted and as a result the strength of the electromagnet will be less , and if there are the same number of turns in one and the other direction, the magnet will not attract anything at all, since the fields will suppress each other.

3. The strength of the electromagnet will also depend on the strength of the current, and it will depend on the voltage applied to the coil and its resistance. The resistance of the coil depends on the length of the wire (the longer, the larger it is) and its cross-sectional area (the larger the cross-section, the lower the resistance). An approximate calculation can be made using the formula - R=p*L/S

4. If the current is too high, the coil will burn out

5. With direct current, the current will be greater than with alternating current due to the influence of inductance reactance.

6. When operating on alternating current, the electromagnet will hum and rattle, its field will constantly change direction, and its traction force will be less (half) than when operating on constant current. In this case, the core for AC coils is made of thin sheet metal, assembled into a single whole, while the plates are isolated from each other with varnish or a thin layer of scale (oxide), the so-called. charge - to reduce losses and Foucault currents.

7. With the same traction force, an alternating current electric magnet will weigh twice as much, and the dimensions will increase accordingly.

8. But it is worth considering that alternating current electromagnets are faster than direct current magnets.

9. DC electromagnet cores

10. Both types of electromagnets can operate on both direct and alternating current, the only question is what strength it will have, what losses and heating will occur.

3 ideas for an electromagnet using improvised means in practice

As already mentioned, the easiest way to make an electromagnet is to use a metal rod and a copper wire, selecting both for the required power. The supply voltage of this device is selected experimentally based on the current strength and heating of the structure. For convenience, you can use a plastic spool of thread or the like, and select a core - a bolt or nail - for its internal hole.

The second option is to use an almost finished electromagnet. Think about electromagnetic switching devices - relays, magnetic starters and contactors. For use on direct current and 12V voltage, it is convenient to use a coil from automotive relays. All you need to do is remove the case, break out the moving contacts and connect the power.

To operate from 220 or 380 volts, it is convenient to use coils; they are wound on a mandrel and can be easily removed. Select the core based on the cross-sectional area of the hole in the coil.

This way you can turn on the magnet from the outlet, and it is convenient to regulate its strength if you use a rheostat or limit the current using a powerful resistance, for example.

An electromagnet is an artificial magnet in which a magnetic field arises and is concentrated in a ferromagnetic core as a result of the passage of electric current through the winding surrounding it, i.e. When current is passed through the coil, the core placed inside it acquires the properties of a natural magnet.

The scope of application of electromagnets is very wide. They are used in electrical machines and devices, in automation devices, in medicine, and in various types of scientific research. Most often, electromagnets and solenoids are used to move some mechanisms, and in industries to lift loads.

For example, a lifting electromagnet is a very convenient, productive and economical mechanism: no maintenance personnel are required to secure and release the transported cargo. It is enough to place an electromagnet on the moving load and turn on the electric current in the electromagnet coil and the load will be attracted to the electromagnet, and to release the load you only need to turn off the current.

The design of an electromagnet is easy to replicate and is essentially nothing more than a core and a coil of conductor. In this article we will answer the question of how to make an electromagnet with your own hands?

How an electromagnet works (theory)

If an electric current flows through a conductor, a magnetic field is formed around this conductor. Since current can only flow when the circuit is closed, the conductor must be a closed loop, such as a circle, which is the simplest closed loop.

Previously, a conductor rolled into a circle was often used to observe the effect of current on a magnetic needle placed in its center. In this case, the arrow is at an equal distance from all parts of the conductor, making it easier to observe the effect of the current on the magnet.

To increase the effect of electric current on a magnet, you can first increase the current. However, if you bend a conductor through which some current flows twice around the circuit it covers, then the effect of the current on the magnet will double.

In this way, this action can be increased many times over by bending the conductor an appropriate number of times around a given circuit. The resulting conducting body, consisting of individual turns, the number of which can be arbitrary, is called a coil.

Let's remember the school physics course, namely that when an electric current flows through a conductor. If the conductor is rolled into a coil, the magnetic induction lines of all turns will add up, and the resulting magnetic field will be stronger than for a single conductor.

The magnetic field generated by electric current, in principle, has no significant differences compared to the magnetic field. If we return to electromagnets, the formula for its traction force looks like this:

F=40550∙B 2 ∙S,

where F is the traction force, kg (force is also measured in newtons, 1 kg = 9.81 N, or 1 N = 0.102 kg); B - induction, T; S is the cross-sectional area of the electromagnet, m2.

That is, the traction force of an electromagnet depends on the magnetic induction, consider its formula:

Here U0 is the magnetic constant (12.5*107 H/m), U is the magnetic permeability of the medium, N/L is the number of turns per unit length of the solenoid, I is the current strength.

It follows that the force with which a magnet attracts something depends on the current strength, the number of turns and the magnetic permeability of the medium. If there is no core in the coil, the medium is air.

Below is a table of relative magnetic permeabilities for different media. We see that for air it is equal to 1, and for other materials it is tens and even hundreds of times greater.

In electrical engineering, a special metal is used for cores; it is often called electrical or transformer steel. In the third line of the table you see “Iron with silicon” whose relative magnetic permeability is 7 * 103 or 7000 H/m.

This is the average value for transformer steel. It differs from the usual one precisely in the silicon content. In practice, its relative magnetic permeability depends on the applied field, but we will not go into details. What does the core do in the coil? An electrical steel core will enhance the magnetic field of the coil by approximately 7000-7500 times!

All you need to remember to begin with is that the material of the core inside the coil depends on it, and the force with which the electromagnet will pull depends on it.

Practice

One of the most popular experiments that are carried out to demonstrate the occurrence of a magnetic field around a conductor is the experiment with metal shavings. The conductor is covered with a sheet of paper and magnetic shavings are poured onto it, then an electric current is passed through the conductor, and the shavings change their location somehow on the sheet. It's almost an electromagnet.

But simply attracting metal shavings is not enough for an electromagnet. Therefore, you need to strengthen it, based on the above - you need to make a coil wound on a metal core. The simplest example would be insulated copper wire wound around a nail or bolt.

Such an electromagnet is capable of attracting various pins, scrapies, and the like.

As a wire, you can use either any wire in PVC or other insulation, or copper wire in varnish insulation such as PEL or PEV, which are used for windings of transformers, speakers, motors, etc. You can find it either new in reels, or reeled from the same transformers.

10 Nuances of making electromagnets in simple words:

1. The insulation along the entire length of the conductor must be uniform and intact so that there are no interturn short circuits.

2. Winding should go in one direction, like on a spool of thread, that is, you cannot bend the wire 180 degrees and go in the opposite direction. This is due to the fact that the resulting magnetic field will be equal to the algebraic sum of the fields of each turn, if you do not go into details, then the turns wound in the opposite direction will generate an electromagnetic field of the opposite sign, as a result the fields will be subtracted and as a result the strength of the electromagnet will be less , and if there are the same number of turns in one and the other direction, the magnet will not attract anything at all, since the fields will suppress each other.

3. The strength of the electromagnet will also depend on the strength of the current, and it will depend on the voltage applied to the coil and its resistance. The resistance of the coil depends on the length of the wire (the longer, the larger it is) and its cross-sectional area (the larger the cross-section, the lower the resistance). An approximate calculation can be made using the formula - R=p*L/S

4. If the current is too high, the coil will burn out

5. With direct current, the current will be greater than with alternating current due to the influence of inductance reactance.

6. When operating on alternating current, the electromagnet will hum and rattle, its field will constantly change direction, and its traction force will be less (half) than when operating on constant current. In this case, the core for AC coils is made of thin sheet metal, assembled into a single whole, while the plates are isolated from each other with varnish or a thin layer of scale (oxide), the so-called. charge - to reduce losses and Foucault currents.

7. With the same traction force, an alternating current electric magnet will weigh twice as much, and the dimensions will increase accordingly.

8. But it is worth considering that alternating current electromagnets are faster than direct current magnets.

9. DC electromagnet cores

10. Both types of electromagnets can operate on both direct and alternating current, the only question is what strength it will have, what losses and heating will occur.

3 ideas for an electromagnet using improvised means in practice

As already mentioned, the easiest way to make an electromagnet is to use a metal rod and a copper wire, selecting both for the required power. The supply voltage of this device is selected experimentally based on the current strength and heating of the structure. For convenience, you can use a plastic spool of thread or the like, and select a core - a bolt or nail - for its internal hole.

The second option is to use an almost finished electromagnet. Think about electromagnetic switching devices - relays, magnetic starters and contactors. For use on direct current and 12V voltage, it is convenient to use a coil from automotive relays. All you need to do is remove the case, break out the moving contacts and connect the power.

To operate from 220 or 380 volts, it is convenient to use coils; they are wound on a mandrel and can be easily removed. Select the core based on the cross-sectional area of the hole in the coil.

This way you can turn on the magnet from the outlet, and it is convenient to regulate its strength if you use a rheostat or limit the current using a powerful resistance, for example.

We make an electromagnet at home. DIY electromagnet calculation for 12 volts

Electromagnets | Everything with your own hands

One day, once again, leafing through a book that I found near a trash can, I noticed a simple, approximate calculation of electromagnets. The title page of the book is shown in photo 1.

In general, their calculation is a complex process, but for radio amateurs, the calculation given in this book is quite suitable. Electromagnets are used in many electrical devices. It is a coil of wire wound on an iron core, the shape of which can be different. The iron core is one part of the magnetic circuit, and the other part, with the help of which the path of the magnetic lines of force is closed, is the armature. The magnetic circuit is characterized by the magnitude of magnetic induction - B, which depends on the field strength and magnetic permeability of the material. That is why the cores of electromagnets are made of iron, which has high magnetic permeability. In turn, the power flux, denoted in the formulas by the letter F, depends on the magnetic induction. F = B S - magnetic induction - B multiplied by the cross-sectional area of the magnetic circuit - S. The power flow also depends on the so-called magnetomotive force (Em), which is determined the number of ampere turns per 1 cm of the path length of the power lines and can be expressed by the formula: Ф = magnetomotive force (Em) magnetic resistance (Rm) Here Em = 1.3 I N, where N is the number of turns of the coil, and I is the strength of the current flowing through the coil in amperes Another component: Rm = L/M S, where L is the average path length of the magnetic power lines, M is the magnetic permeability, and S is the cross-section of the magnetic circuit. When designing electromagnets, it is highly desirable to obtain a large power flux. This can be achieved by reducing the magnetic resistance. To do this, you need to select a magnetic core with the shortest path length of the power lines and the largest cross section, and the material should be an iron material with high magnetic permeability. Another way of increasing the power flow by increasing the ampere turns is not acceptable, since in order to save wire and power, one should strive to reduce the ampere turns. Usually, calculations of electromagnets are made according to special schedules. To simplify the calculations, we will also use some conclusions from the graphs. Suppose you need to determine the ampere turns and power flux of a closed iron magnetic circuit, shown in Figure 1a and made of the lowest quality iron.

Looking at the graph (unfortunately, I didn’t find it in the appendix) of the magnetization of iron, it is easy to see that the most advantageous magnetic induction is in the range from 10,000 to 14,000 lines of force per 1 cm2, which corresponds to from 2 to 7 ampere turns per 1 cm. For winding coils with the smallest number of turns and more economical in terms of power supply, for calculations it is necessary to take exactly this value (10,000 power lines per 1 cm2 at 2 ampere turns per 1 cm of length). In this case, the calculation can be made as follows. So, with the length of the magnetic circuit L = L1 + L2 equal to 20 cm + 10 cm = 30 cm, 2 × 30 = 60 ampere turns will be required. If the diameter D of the core (Fig. 1, c) is taken equal to 2 cm, then its area will be equal to: S = 3.14xD2/4 = 3.14 cm2. Here the excited magnetic flux will be equal to: Ф = B x S = 10000 x 3.14 = 31400 lines of force. The lifting force of the electromagnet (P) can also be approximately calculated. P = B2 S/25 1000000 = 12.4 kg. For a two-pole magnet this result should be doubled. Therefore, P = 24.8 kg = 25 kg. When determining the lifting force, it must be remembered that it depends not only on the length of the magnetic circuit, but also on the area of contact between the armature and the core. Therefore, the armature must fit exactly against the pole pieces, otherwise even the slightest air gaps will cause a strong reduction in lift. Next, the electromagnet coil is calculated. In our example, a lifting force of 25 kg is provided by 60 ampere turns. Let us consider by what means the product N J = 60 ampere turns can be obtained. Obviously, this can be achieved either by using a large current with a small number of coil turns, for example 2 A and 30 turns, or by increasing the number of coil turns with a decreasing current, for example 0.25 A and 240 turns. Thus, in order for the electromagnet to have a lifting force of 25 kg, 30 turns and 240 turns can be wound on its core, but at the same time change the value of the supply current. Of course, you can choose a different ratio. However, changing the current value within large limits is not always possible, since it will necessarily require changing the diameter of the wire used. Thus, during short-term operation (several minutes) for wires with a diameter of up to 1 mm, the permissible current density, at which the wire does not overheat, can be taken equal to 5 a/mm2. In our example, the wire should have the following cross-section: for a current of 2 a - 0.4 mm2, and for a current of 0.25 a - 0.05 mm2, the wire diameter will be 0.7 mm or 0.2 mm, respectively. Which of these wires should be wound? On the one hand, the choice of wire diameter can be determined by the available assortment of wire, on the other hand, by the capabilities of the power sources, both in terms of current and voltage. Indeed, two coils, one of which is made of thick wire of 0.7 mm and with a small number of turns - 30, and the other of which is made of wire of 0.2 mm and a number of turns of 240, will have sharply different resistance. Knowing the diameter of the wire and its length, you can easily determine the resistance. The length of the wire L is equal to the product of the total number of turns and the length of one of them (average): L = N x L1 where L1 is the length of one turn, equal to 3.14 x D. In our example, D = 2 cm, and L1 = 6, 3 cm. Therefore, for the first coil the length of the wire will be 30 x 6.3 = 190 cm, the resistance of the winding to direct current will be approximately equal to? 0.1 Ohm, and for the second - 240 x 6.3 = 1,512 cm, R? 8.7 Ohm. Using Ohm's law, it is easy to calculate the required voltage. So, to create a current of 2A in the windings, the required voltage is 0.2V, and for a current of 0.25A - 2.2V. This is the elementary calculation of electromagnets. When designing electromagnets, it is necessary not only to make the indicated calculations, but also to be able to choose the material for the core, its shape, and think through the manufacturing technology. Satisfactory materials for making mug cores are bar iron (round and strip) and various. iron products: bolts, wire, nails, screws, etc. To avoid large losses on Foucault currents, cores for alternating current devices must be assembled from thin sheets of iron or wire isolated from each other. To make iron “soft,” it must be annealed. The correct choice of core shape is also of great importance. The most rational of them are ring and U-shaped. Some of the common cores are shown in Figure 1.

Discuss this article on the “Radio electronics, questions and answers” forum.

www.kondratev-v.ru

An electromagnet is a very useful device that is widely used in industry and in many areas of human activity. Although this device may seem complex in its design, it is easy to manufacture and a small home electromagnet can be made at home using improvised materials.

Let's watch the process of creating this homemade product in the video:

In order to make a small electromagnet at home we will need: - Iron nail or bolt; - Copper wire; - Sandpaper; - Alkaline battery.

At the very beginning, it should be noted that it is not advisable to use too thick wire. Copper wire with a diameter of one millimeter is perfect for a future electromagnet. As for the size of the nail or bolt, the ideal length would be 7-10 centimeters.

So, let's start making a mini electromagnet. First we need to wrap the copper wire around the bolt. It is important to pay attention to the fact that each turn fits tightly to the previous one.

You need to wind the wire so that there is a piece of wire left at both ends.

All that remains is to connect our wires to the source, namely the alkaline battery. After this, our bolt will attract metal elements.

The operating principle of an electromagnet is very simple. When an electric current passes through a coil with a core, a magnetic field is formed, which attracts metal elements. The power of the electromagnet depends on the density of the coil and the number of layers of copper wire, as well as on the current strength.

usamodelkina.ru

How to make an electromagnet with your own hands

The article describes how to make a simple electromagnet with your own hands at home.

An electromagnet is a magnet that runs on electricity. Unlike a permanent magnet, the strength of an electromagnet can be easily changed by changing the amount of electric current flowing through it, and the poles of an electromagnet can be easily changed by changing the flow of electricity. An electromagnet works because an electric current creates a magnetic field.

Making an electromagnet with your own hands is quite simple. All you have to do is wrap some insulated copper wire around the iron core. If you connect this wire to a battery, electric current will flow through the winding and the iron core will become magnetized at the same time. When the battery is disconnected, the iron core will lose its magnetism. If you want to make an electromagnet with your own hands, then follow these steps:

Step 1 - You will need the following materials:

- One iron nail approximately fifteen centimeters long

- Three meters of insulated copper wire

- One or more batteries, possibly an accumulator

- A pair of ordinary wires to connect to the battery

- Insulation tape

Step 2 - Remove some of the insulation from the wires

To create a good connection, the ends of the copper wire must be stripped. Remove a few centimeters of insulation from each end of the wire. Then strip the ends of the regular wires to connect to the battery.

Step 3 - Wrap the copper wire around the nail

Carefully wrap the wire evenly around the nail. The more insulated wire you wrap around the nail, the stronger your electromagnet will be. Make sure that the part of the bare copper wire that is intended to connect it to the battery is not in contact with the core.

When you wrap the wire around the nail, be sure to do it in one direction. The thing is that the direction of the magnetic field depends on the direction of the electric current that creates it. The movement of electric charges creates a magnetic field. If you could see the magnetic field around a wire, it would look like a series of circles around the wire. If an electric current flows through a winding twisted counterclockwise, then the created magnetic field rotates around the wire in the same direction. If the direction of the electric current is reversed, the magnetic field also reverses direction and moves clockwise. If you wrap one wire around a nail in one direction and another wire in the other direction, the magnetic fields from the different sections will fight each other and cancel out, reducing the strength of your magnet.

Step 4 - Connecting the Battery

Connect the two ends of ordinary wires to the ends of copper wires, insulate the connections between the wires with insulating tape. Then connect one end of the regular wire to the positive terminal of the battery, and the other end of the wire to the negative terminal of the battery. If everything went well, your electromagnet will start working!

There is no need to worry about which end of the wire is connected to the positive terminal of the battery and which to the negative terminal. Your magnet will work equally well in both cases. The only thing that will change is the polarity of your magnet. One end of your magnet will be its north pole, and the other end will be its south pole. Reversing the battery connection will reverse the poles of your electromagnet.

How to make an electromagnet stronger

The more turns of wire your electromagnet has, the better. However, keep in mind that the further the wire is from the iron core, the less effective the magnetic field will be.

The more current that passes through the wires, the better. Attention! Too much current can be dangerous! When electricity passes through a wire, some of the energy is lost as heat. The more current flowing through the wire, the more heat is created. When the current is high, your wiring can become very hot and may even melt the insulation on it.

Try experimenting with different cores. A thicker base can increase the magnet's strength. Not all iron material is suitable for a core; some iron cannot be magnetized. You can test your cores with a permanent magnet. If a permanent magnet isn't attracted to your nail, it won't make a good electromagnet.

www.tesla-tehnika.biz

Along with permanent magnets, since the 19th century, people began to actively use variable magnets in technology and everyday life, the operation of which can be regulated by the supply of electric current. Structurally, a simple electromagnet is a coil of electrical insulating material with a wire wound on it. If you have a minimum set of materials and tools, it is not difficult to make an electromagnet yourself. We will tell you how to do it in this article.

When electric current passes through a conductor, a magnetic field appears around the wire; when the current is turned off, the field disappears. To enhance the magnetic properties, a steel core can be introduced into the center of the coil or the current can be increased.

Use of electromagnets in everyday life

Electromagnets can be used to solve a number of problems:

- for collecting and removing steel filings or small steel fasteners;

- in the process of making various games and toys together with children;

- for electrifying screwdrivers and bits, which allows you to magnetize screws and facilitate the process of screwing them;

- for conducting various experiments on electromagnetism.

Making a simple electromagnet

The simplest electromagnet, quite suitable for solving a small range of practical household problems, can be made with your own hands without using a coil.

For work, prepare the following materials:

- steel rod with a diameter of 5-8 millimeters or a 100 nail;

- copper wire in varnish insulation with a diameter of 0.1-0.3 millimeters;

- two pieces of 20 centimeters of copper wire in PVC insulation;

- insulating tape;

- source of electricity (battery, accumulator, etc.).

From tools, prepare scissors or wire cutters (side cutters) for cutting wires, pliers, and a lighter.

The first stage is winding the electrical wire. Wind several hundred turns of thin wire directly onto the steel core (nail). Carrying out this process manually takes quite a long time. Use a simple winding device. Clamp the nail into the chuck of a screwdriver or electric drill, turn on the tool and, guiding the wire, wind it. Wrap pieces of larger diameter wire to the ends of the wound wire and insulate the contact points with insulating tape.

When operating the magnet, all that remains is to connect the free ends of the wires to the poles of the current source. The distribution of connection polarity does not affect the operation of the device.

Using the switch

For ease of use, we suggest slightly improving the resulting diagram. Two more elements should be added to the above list. The first of them is the third wire in PVC insulation. The second is a switch of any type (keyboard, push-button, etc.).

Thus, the electromagnet connection diagram will look like this:

- the first wire connects one contact of the battery to the contact of the switch;

- the second wire connects the second contact of the switch with one of the contacts of the electromagnet wire;

the third wire completes the circuit, connecting the second contact of the electromagnet to the remaining contact of the battery.

Using a switch, turning on and off the electromagnet will be much more convenient.

Coil based electromagnet

A more complex electromagnet is made on the basis of a coil of electrical insulating material - cardboard, wood, plastic. If you don’t have such an element, it’s easy to make it yourself. Take a small tube from the indicated materials and glue a couple of washers with holes to it at the ends. It is better if the washers are located at a small distance from the ends of the coil.

Further actions are similar to the process described above:

wind a sufficient amount of copper wire in varnish insulation onto the coil;  install a steel core inside the coil;

install a steel core inside the coil;  Assemble the diagram for connecting the electromagnet to the current source described above and use the device for its intended purpose.

Assemble the diagram for connecting the electromagnet to the current source described above and use the device for its intended purpose.

Dear readers, if you have any questions, please ask them using the form below. We will be glad to communicate with you;)

stroi-specialist.ru

DIY electromagnet: how to make an electromagnet

Households require different tools from time to time. Often you have to make various devices with your own hands, including an electromagnet. This device removes metal shavings very effectively and makes it easy to find small metal objects. Sometimes home craftsmen just want to experiment, remembering their knowledge from the school physics course.

Electromagnet device

A classical electromagnet is a device in which a magnetic field appears when an electric current passes through it. In the simplest electromagnet, such a field can form even around an ordinary conductor if it is energized.

The circuit of the simplest electromagnet includes a ferromagnetic core with a wound winding. When electric current flows through the winding, a powerful magnetic field is formed in the core. To perform mechanical actions, the structure is equipped with a moving part called an anchor. Aluminum or copper insulated wire is used for winding. This circuit diagram is the basis for creating similar electromagnets with your own hands at home.

Making an electromagnet at home

To make an electromagnet with your own hands, you first need to select the material for the core. The simplest and most suitable option would be a large nail, 100 to 200 mm long. It must first be heated very much, and then allowed to cool and cleaned of scale. After this, the nail is bent exactly in half, and the head and tip are sawed off with a hacksaw.

The second stage will be making the coil. The design of the reel includes the following elements: a rectangular paper neck (48x37 mm), paper stop rims (48x3 mm) and round cardboard rims with a hole in the middle. Their outer and inner diameters will be 19 and 7 mm, respectively.

After preparing the parts, you can begin assembling the electromagnet. The neck on the narrower side is wound loosely around the nail and fixed with glue. Next, cardboard rims are put on the lower and upper parts of the neck. The thrust rims are lubricated with glue, wound around the edges of the neck and glued to the rims. The glue should dry well in all areas.

A wire approximately 15-20 meters long is suitable for winding. The wire is wound onto a reel so that ends of 10 centimeters remain at the edges. The winding must be even so that all turns fit tightly together. The power of the future electromagnet completely depends on this. The greatest difficulty lies in winding the first layer. Each finished row is wrapped in two layers of thin paper. At the end of the winding, the entire coil is wrapped on top with electrical tape. The remaining ends of the winding must be stripped for further connection.

All that remains is to attach the switch and battery to the resulting structure. Thus, the electromagnet will be completely made with your own hands.

Regardless of why a person needs a magnet, it can easily be made at home. When you have such a thing at hand, you can use it not only to have fun picking up various small pieces of iron from the table, but also to find a useful use for it, for example, to find a needle dropped on the carpet. In this article you will learn how easy it is to make an electromagnet with your own hands at home.

A little physics

As we remember (or don’t remember) from physics lessons, in order to convert electric current into a magnetic field, we need to create induction. Inductance is created using an ordinary coil, inside which this field arises and is transmitted to the steel core around which the coil is wound.

Thus, depending on the polarity, one end of the core will emit a field with a minus sign, and the opposite end will emit a field with a plus sign. But visual magnetic abilities are not affected in any way by polarity. So, when you are done with physics, you can begin decisive action to create a simple electromagnet with your own hands.

Materials for making the simplest magnet

First of all, we need any inductor with a copper wire wound around the core. This can be a regular transformer from any power supply. An excellent way to create electromagnets is to wind them around the narrowed back of picture tubes of old monitors or televisions. The conductor threads in transformers are protected by insulation consisting of an almost invisible layer of special varnish that prevents the passage of electric current, which is exactly what we need. In addition to the indicated conductors, to create an electromagnet with your own hands you also need to prepare:

- A regular one and a half volt battery.

- Scotch tape or tape.

- Sharp knife.

- Hundreds of nails.

The process of making a simple magnet

We start by removing the wires from the transformer. As a rule, its middle is located inside the steel frame. You can, after removing the surface insulation on the coil, simply unwind the wire, dragging it between the frames and the coil. Since we don't need a lot of wire, this method is the most acceptable here. When we have released enough wire, we do the following:

- We wind the wire removed from the transformer coil around a nail, which will serve as a steel core for our electromagnet. It is advisable to make turns as often as possible, pressing them tightly against each other. Do not forget to leave a long end of the wire at the initial turn, through which our electromagnet will be powered to one of the poles of the battery.

- When we reach the opposite end of the nail, we also leave a long conductor for powering. We cut off the excess wire with a knife. To prevent the spiral we wound from unraveling, you can wrap it with tape or tape.

- We strip both ends of the wire coming from the wound nail from the insulating varnish with a knife.

- We lean one end of the stripped conductor against the positive of the battery and secure it with tape or tape so that the contact is well maintained.

- We wind the other end to the minus in the same way.

The electromagnet is ready for use. By scattering metal clips or tacks on the table, you can check its functionality.

How to make a more powerful magnet?

How to make an electromagnet with more powerful magnetic properties with your own hands? The strength of magnetism is influenced by several factors, and the most important one is the electrical current of the battery we use. For example, by making an electromagnet from a square 4.5 volt battery, we will triple the strength of its magnetic properties. The 9-volt crown will give an even more powerful effect.

But do not forget that the stronger the electric current, the more turns will be required, since the resistance with a small number of turns will be too strong, which will lead to strong heating of the conductors. If they are heated too much, the insulating varnish may begin to melt, and the turns will begin to short-circuit to each other or to the steel core. Both will sooner or later lead to a short circuit.

Also, the strength of magnetism depends on the number of turns around the magnet core. The more there are, the stronger the induction field will be, and the stronger the magnet will be.

Making a more powerful magnet

Let's try to make a 12 volt electromagnet with our own hands. It will be powered by a 12-volt AC power supply or a 12-volt car battery. To manufacture it, we will need a much larger amount of copper conductor, and therefore we should initially remove the internal coil with copper wire from the prepared transformer. A grinder is the best way to extract it.

What we need for production:

- A steel horseshoe from a large padlock, which will serve as our core. In this case, it will be possible to magnetize the pieces of iron at both ends, which will further increase the lifting capacity of the magnet.

- Coil with copper wire in varnished insulation.

- Insulating tape.

- Unnecessary 12 volt power supply or car battery.

The process of making a powerful 12-volt magnet

Of course, any other massive steel pin can be used as a core. But a horseshoe from an old castle will do just fine. Its bend will serve as a kind of handle if we start lifting loads of impressive weight. So, in this case, the process of making an electromagnet with your own hands is as follows:

- We wind the wire from the transformer around one of the horseshoes. We place the coils as tightly as possible. The curve of the horseshoe will interfere a little, but that's okay. When the length of the side of the horseshoe ends, we lay the turns in the opposite direction, on top of the first row of turns. We make a total of 500 turns.

- When the winding of one half of the horseshoe is ready, wrap it with one layer of electrical tape. The original end of the wire, intended for recharge from a current source, is brought out to the upper part of the future handle. We wrap our coil on the horseshoe with another layer of electrical tape. We wind the other end of the conductor to the bending core of the handle and make another coil on the other side.

- We wind the wire on the opposite side of the horseshoe. We do everything the same as in the case of the first side. When 500 turns have been laid, we also remove the end of the wire for power supply from an energy source. For those who don't understand, the procedure is clearly shown in this video.

The final stage of making an electromagnet with your own hands is recharging to the energy source. If it is a battery, we extend the ends of the stripped conductors of our electromagnet using additional wires, which we connect to the battery terminals. If this is a power supply, cut off the plug going to the consumer, strip the wires and screw a wire from the electromagnet to each one. Insulate with electrical tape. We plug the power supply into the outlet. Congratulations. You have made with your own hands a powerful 12-volt electromagnet that is capable of lifting loads over 5 kg.

An electromagnet is a special type of magnet in which a magnetic field is created by applying an electric current to that magnet. In the absence of current, the magnetic field disappears, and this feature is useful in many areas of electrical engineering.

An electromagnet is a fairly simple device, so its manufacture is quite simple and inexpensive. Even some schools show students the basic technique of making electromagnets using a wire, a nail and a battery. And students watch in amazement as the quickly built electromagnet lifts lightweight metal objects such as paper clips, pins and nails. But you can also make your own powerful DC electromagnet that is several times stronger than the ones they make in classrooms.

So, first, place your fingers on the wire 50 centimeters from the end. Wrap the wire around the top of the steel pin (you can use a large nail), starting from where your fingers rest on the wire. Carry out the winding smoothly and carefully until the very end of the pin. Once you reach the end, begin wrapping the wire over the first layer, making a new wrap towards the top of the pin. Then wrap the wire back over the pin towards the bottom, making a second layer. Cut the wire from the coil, leaving a 50cm piece of wire at the bottom of the pin.

Next, connect the top copper wire to the negative terminal and the bottom copper wire to the positive terminal of the battery. Make sure the wires make good contact with the terminals. It is advisable to have a button to turn on the battery, or you can put a contactor on one end of the wire to supply power to the electromagnet, completing the circuit when needed. After successful assembly, check the functionality of the electromagnet by bringing various metal objects to it.

It should be noted that the more powerful the battery you use, the more powerful your electromagnet will be. Increasing the battery voltage and using more layers of the electromagnetic coil increases the power of the electromagnet. But at the same time, you need to monitor the condition of the wire, since it can become very hot, which can ultimately be dangerous. If the thickness of the wire is small, then such wire will generate more heat.

.

If you want interesting and useful materials to be published more often and with less advertising,

You can support our project by donating any amount for its development.